AirStar separator rolls provide continuous and consistent performance for extended periods of time when properly installed and recommended maintenance procedures are followed.

Because the rotating roll rides on a film of air, which acts as the lubricant, the air must be clean and dry. To assure adequate airflow through the bearing during operation, proper pressure is required at the shaft inlet. This can range from 50 to 80 PSIG depending on the application.

When the machine or station is shut down, pressure should be maintained at a level sufficient to prevent contaminants from entering the bearing by capillary action or otherwise. Pressure should not be reduced during shutdown while the roll is rotating.

Any air leaks in the supply system should be promptly eliminated. All connections to the bearing must be sealed. Filters and drains should be checked regularly.

The roll should be kept clean and free of yarn or finish build-up to prevent unwanted additional loading on the bearing. This will also promote proper exhausting of air from the bearing. To clean, a non-oil-based solvent is recommended with care taken to prevent entry into the bearing.

Chipping, denting, or repositioning of the bearing components because of disassembly can destroy the balance and precision of the bearing. Force should not be applied through the roll to the shaft during installation, removal, or when removing wraps from the roll. To protect the bearing from severe machine vibrations, a damping mount should be employed.

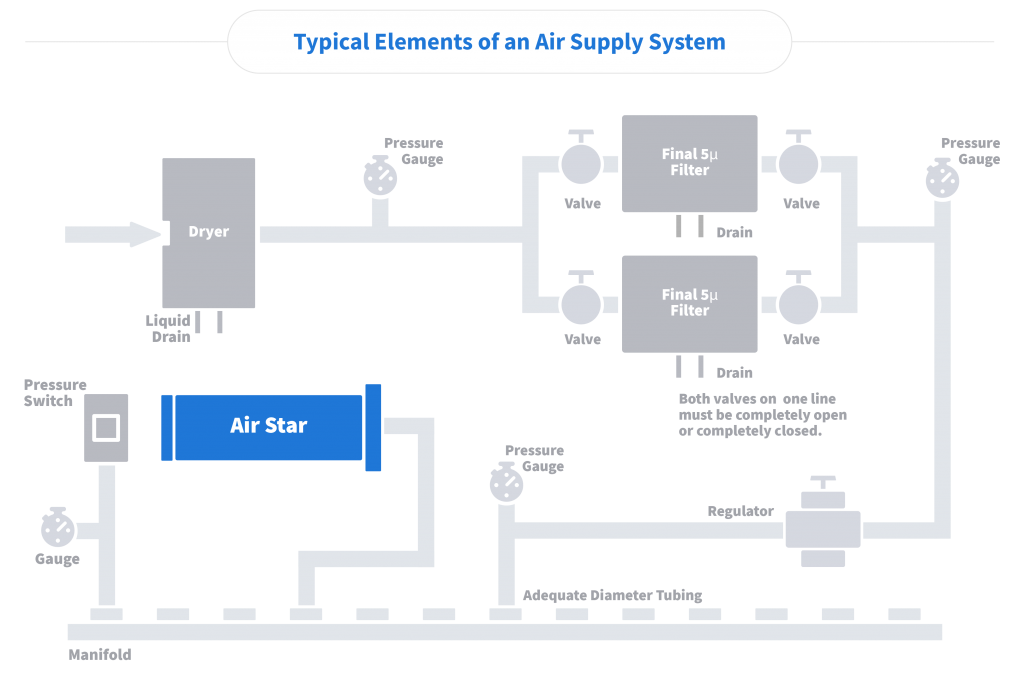

Air Supply System

The use of an air dryer is recommended to remove moisture from the air that is to be filtered.

The final filters should be capable of removing solid and liquid particles greater than five microns. Filters should also have drains for disposal of trapped oil and water. The two final filters should be installed in parallel so one filter can be changed while the other is being used. A change in the pressure differential between the gauges mounted on either side of the filters indicates the filters need to be changed.

A manifold is an effective device for distributing air to AirStar bearings if more than one bearing is to be installed.

Piping and manifold size must be large enough to provide proper pressure and sufficient flow to each bearing. The manifold inlet should be centered to minimize the pressure drop to all the bearings. Fittings should be located on the top of the manifold to avoid possible drainage of fluid onto the bearings. When a bearing is disconnected, these fittings should automatically curtail flow to avoid affecting the air supply to other operational bearings.

A pressure gauge and switch should be mounted on the manifold where the pressure is lowest, which is the farthest point from the air inlet.

The pressure switch should be set at the minimum allowable operating pressure. If the pressure falls below the minimum value, the switch should shut the machine down to protect the AirStar bearings and the fiber quality, or it should activate an auxiliary air supply, if continuous operation must be maintained.

All lines from the filters to the AirStar bearings must be clean and corrosion resistant.

Contaminants from prior unfiltered usage must be removed.